In air-conditioning installations, with the experience of Legionella, it is now mandatory to keep such a log, as well as a record of hygiene testing to determine the non-existence of bacteria.

HVAC COOLING TOWER DESIGN FULL

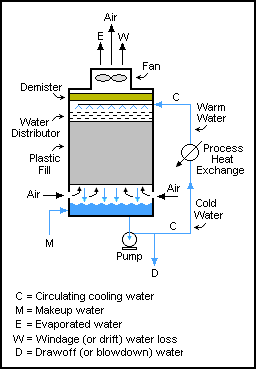

This is true of every cooling tower, from the largest natural-draught tower to the smallest packaged unit.Īll cooling tower operators should keep a full maintenance and working log to enable proper control to be maintained on the water quality and treatment and the operating efficiency, enabling planning of maintenance and operating procedures to be continually be monitored and updated as required. Having selected and purchased a cooling tower, it needs regular maintenance, as does any other part of the plant. Snow CEng, MIMechE, HonFSOE, HonFIPlantE, HonFIIPE, in Plant Engineer's Reference Book (Second Edition), 2002 21.8 Operation The primary benefit is that high pressure drops through the tower are possible, enabling a more compact design and indoor installations. Forced draft designs typically require more motor power than equivalent induced draft towers because they are usually equipped with centrifugal blower type fans. The low exit velocity is more prone to recirculation. This creates high entering and low exiting air velocities. Towers range from 3 to 160,000 m 3/h (15 to 700,000 gpm).įorced draft towers have fans at the air intake to the tower. Location of the fan in the warm air stream provides excellent protection against icing of the mechanical components.

This produces low entering and high exit air velocities, reducing the possibility of recirculation, in which discharged air flows back into the air intake. Induced draft towers have fans at the discharge that pull the air through. Countercurrent-induced draft towers are the most prevalent in the process industries, capable of cooling water within just over 1 ☌ (2 ☏) of the wet-bulb air temperature. Most packaged cooling towers use fans to force or draw air through the tower. Stephen Hall, in Branan's Rules of Thumb for Chemical Engineers (Fifth Edition), 2012 Mechanical Draft Cooling Towers In general, a minimum distance of 15–20 m of clear area should be allocated for air movement about the tower.

This is a traffic hazard, because in certain locations, ice can form in winter. Access RoadsĪccess is required for the essential maintenance of pumps, chemical dosing equipment, and handling trash screens.Ĭooling towers lose water by evaporation and entrainment, resulting in a water spray and fog on the downwind side of the tower, making any roads continually wet.

Noise levels of larger cooling towers can be quite high and may become objectionable if the tower is located too close to continually occupied work areas, such as offices and control buildings. The gives both long sides an equal intake of fresh air.Ĭooling towers should not be downwind or adjacent to fired heaters, flare stacks, or any heat-producing items, as these raise the ambient air temperature and reduce the towers cooling efficiency. Prevailing WindsĬooling towers should be located with their small side toward the prevailing wind. Factors affecting the location of cooling towers, other than convenience to water supply and return, are the prevailing wind, noise, and access roads. Rutger Botermans, Peter Smith, in Advanced Piping Design, 2008 8.3.2 LayoutĪ cooling tower is one of the larger items of equipment, in terms of ground area, that must be located on a site plan.

0 kommentar(er)

0 kommentar(er)